HIGH-END MODEL

This machine adapt electrical plate adjustment,PLC and imported electronic components,feeding section adopts independent electrical control,operation on rail with stable performance and easy to control and operate.This machine is specialized for cardboard and corrugated cartons,its correction function make corrugated cartons perfectly meeting the requirements of packing industry.(We can customize for other sizes.)

Characteristics

| Model | SHH-1050FS |

| Paper Material | 200-800g cardboard and E, F corrugated paper. |

| Max. Liner speed | Max.350m/min |

| Feeding Way | Automatically and continuously feeding. |

| Way of Folding in reverse | Fold 1 and fold 3 are 180 degree and 135 degree Fold 2 and fold 4 are 180 degree Bottom folded and glued 4&6 corner |

| Glue Material | Water-base cold glue. |

| Electric Power | 3P 380V 50Hz |

| Main Power | 14kW |

| Weight | 7.5T |

| Over Dimension | 16.5×1.7×1.7m |

Technical Parameter

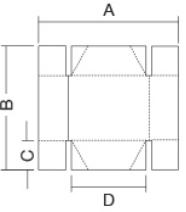

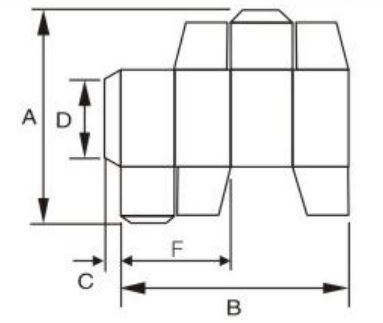

| Four corner box type and size (mm) | |

| Model | SHH-1050FS |

| A | 190 – 1000 |

| B | 130 – 800 |

| C | 30 – 150 |

| D | 130 – 750 |

| Six corner box type and size (mm) | |

| Model | SHH-1050FS |

| A | 290 – 1000 |

| B | 130 – 800 |

| C | 30 – 150 |

| D | 100 – 500 |

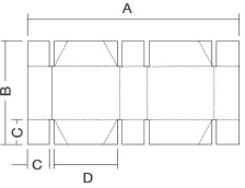

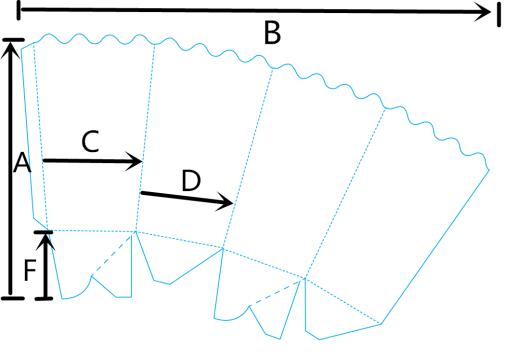

| Lock bottom carton type and folded box size:(mm) | |

| Model | SHH-1050FS |

| A | 200-600 |

| B | 250-850 |

| C | Min:15 |

| D | Min:80 |

| F | Min:130 |

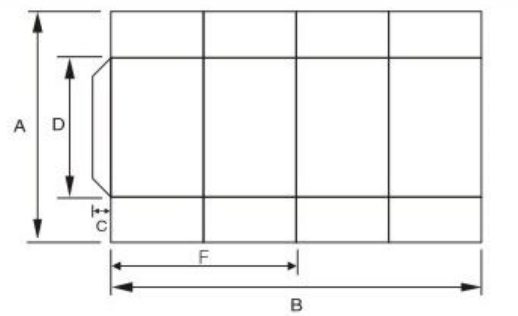

| Common box type and size:(mm) | |

| Model | SHH-1050FS |

| A | 150-700 |

| B | 280-1050 |

| C | Min:15 |

| D | Min:80 |

| F | Min:130 |

| Flat box type and size:(mm) | |

| Model | SHH-1050FS |

| A | 150-700 |

| B | 280-1050 |

| C | Min:15 |

| D | Min:80 |

| F | Min:130 |

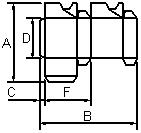

| Pop corn box type and size:(mm) | |

| Model | SHH-1050FS |

| A | 150-600 |

| B | 180-950 |

| C(min) | 40mm |

| D(min) | 35mm |

| F(min) | 20mm |

Sample Box