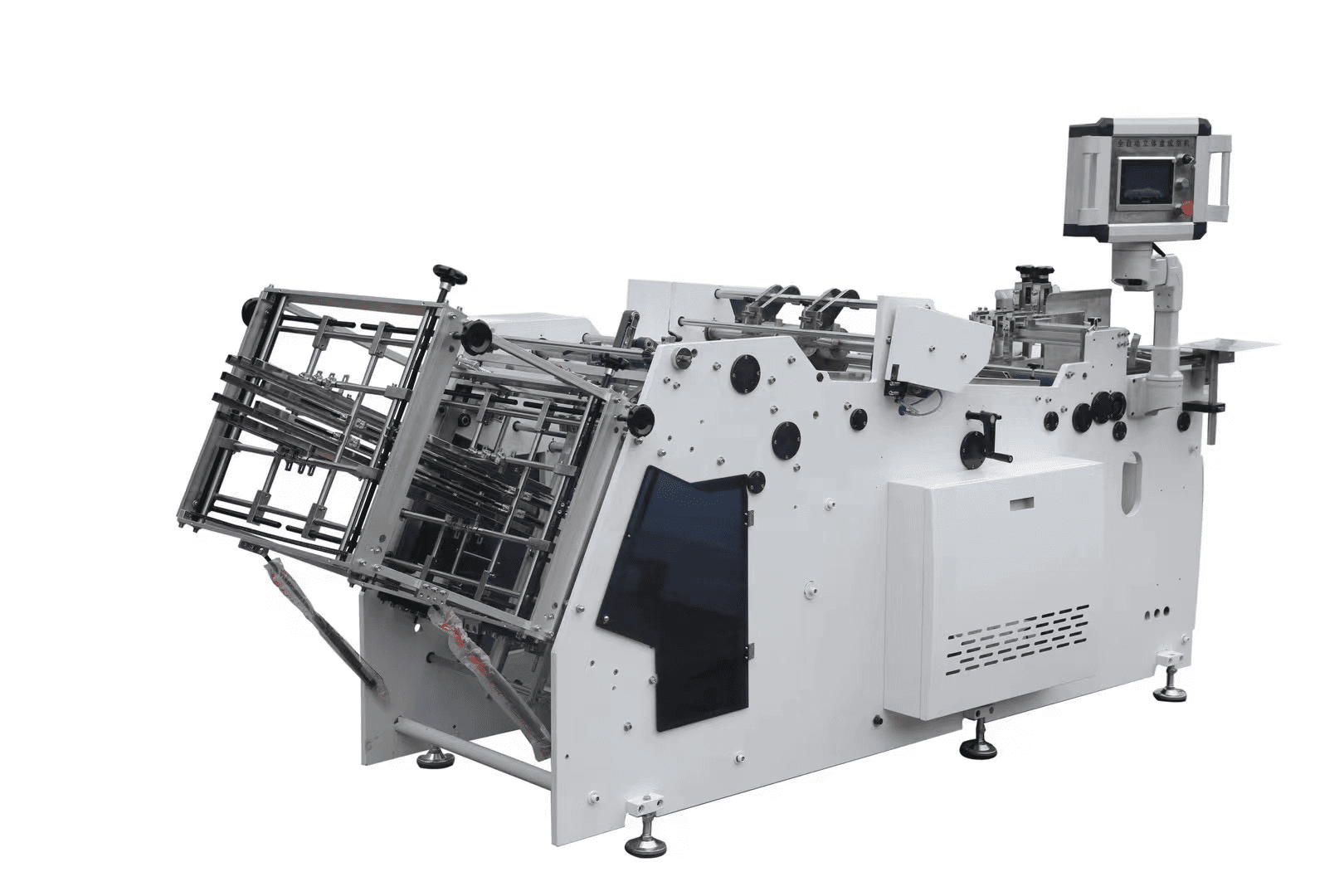

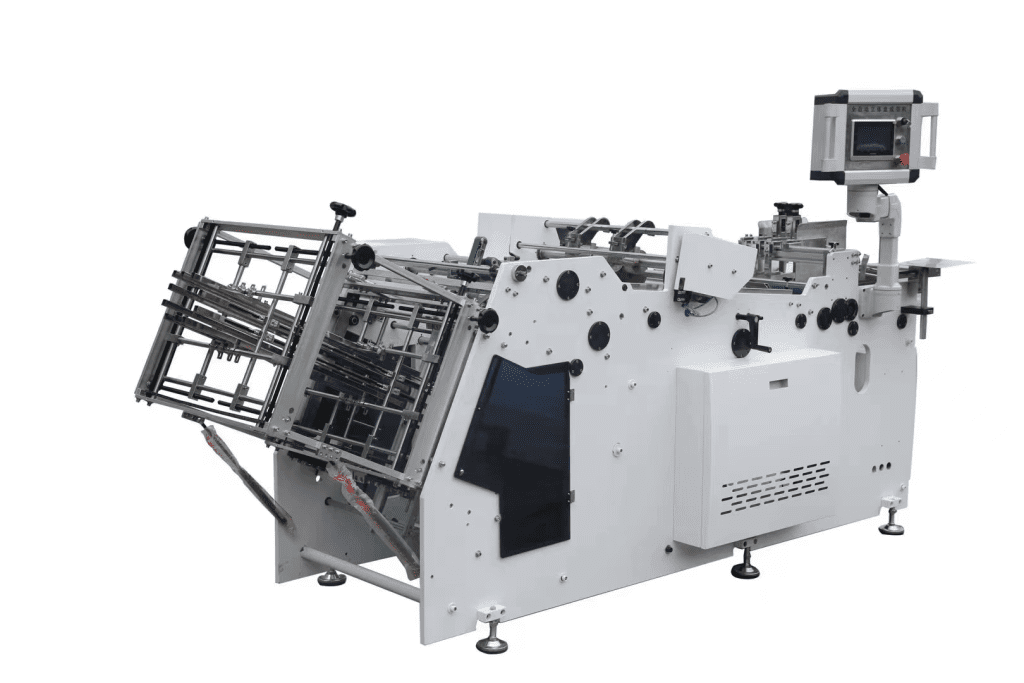

The carton erecting machine is highly efficient.It can be customized to do different size and shaped boxes through changing mold. (hamburger box, fried chips box, paper tray, noodle box, lunch box and other food container. ) It use fours servo motors to make the machine adjustment more easily.

Main function:

1. The host speed setting, servo motor automatic tracking

2. Automatic counting, batches calculation, automatic mark

3. Setting length of the paper-out.

4. Roll on glue automatically.

5. Gluing automatically.

Technical Parameters:

| Paper specification | 60*100–320*450(㎜) | ||

| Suitable material | 200-600g/m2 paper | ||

| Paper thickness | Max. 1.5mm | ||

| Production speed | 60—220pcs/minute | ||

| Max. Feeding paper width | 580㎜ | Imported Voltage | |

| Paper Forming Servo Motor | 8.0KW | 3phases 380V/50HZ

Huichuan brand

|

|

| Feeding Servo Motor | 0.75KW | ||

| Main Host Servo Motor | 1.3KW | ||

| Paper down deceleration Servo motor | 1.3KW | ||

| Machine Weight | 2000KG | ||

| Machine size | 3500*1600*1600mm | ||

| Package size | 3600*1600*1860MM | ||

| Main Parts | Solenoid valve | Two and Five Links | Taiwan Airtac |

| Slide rail | Linear guideway | Taiwan Hiwin | |

| Belt | Feeding belt | USA EP | |

| Electrical components | Low voltage electrical parts | Chint | |

| Relay | Huichuan | ||

|

Driving system |

PLC | Huichuan | |

| Touch screen | WEINVIEW | ||

We export to New Zealand,Germany,Italy,France.