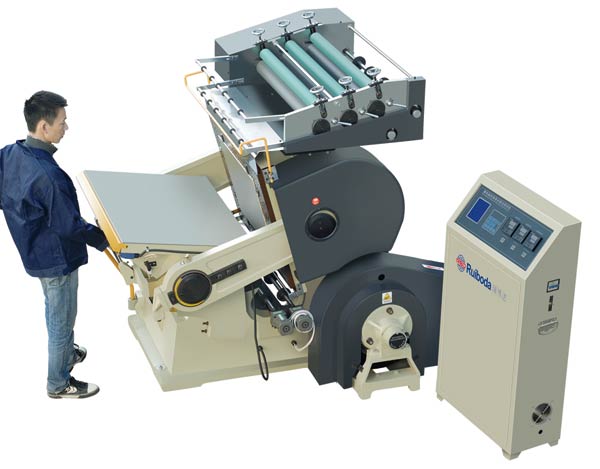

This model gilding, cutting & mark pressurized machine is product of new generation with clockwork precision and marked effect. It is used for gilding-printing all kinds of colored electro-chemical aluminum, marking a concave-convex, die-cutting pictures, trade mark, advertisement of sample, boxes, cover of books and new year card highly decorations and printing materials. It is the optimum equipment for printing, packing, decoration and plastic industries with materials including paper, cardboard, plastic, leather matter.

Features:

●High strength due to one piece casting by using top-ranking material for machine body.

●Single plate electromagnetic clutch is sensitive and reliable.

●Operating position is reasonably arranged, moving-bed can be opened to its optimum.

● computer controlled is stable.

●Skipping is accurate, so as to save foils.

●With three functions of continuous creasing and cutting, opening dwell operation and closing dwell operation and large dwell adjusting range.

●Safety system is reliable.

★All models can be optional: Air brake clutch, Pneumatic jacking device, Infra-red light safety device, Speed-adjustment device, Centralized Automatic oil pump, Centralized manual oil pump.

Technical Parameter

| Model | TYMB-1100 |

| Max. Platen Working Area | 1100x800mm |

| Max. Gilding Printing Area | 1080x780mm |

| Max. Foil Feed Length | 800mm |

| Foil Feeding Roller Group Number | 3Groups |

| Electric Plate Region | 3region |

| Range of Skip Order | 0-99 times |

| Speed ( Strokes/Min) | 20±2 |

| Main Motor | 4kW |

| Total Power | 16kW |

| Total Weight | 5000kgs |

| Overall Dimensions | 2250x2200x2000mm |

Nodular Cast Honeycombs plate: rapid heating temperature uniformity, easy and accurate installation templates.