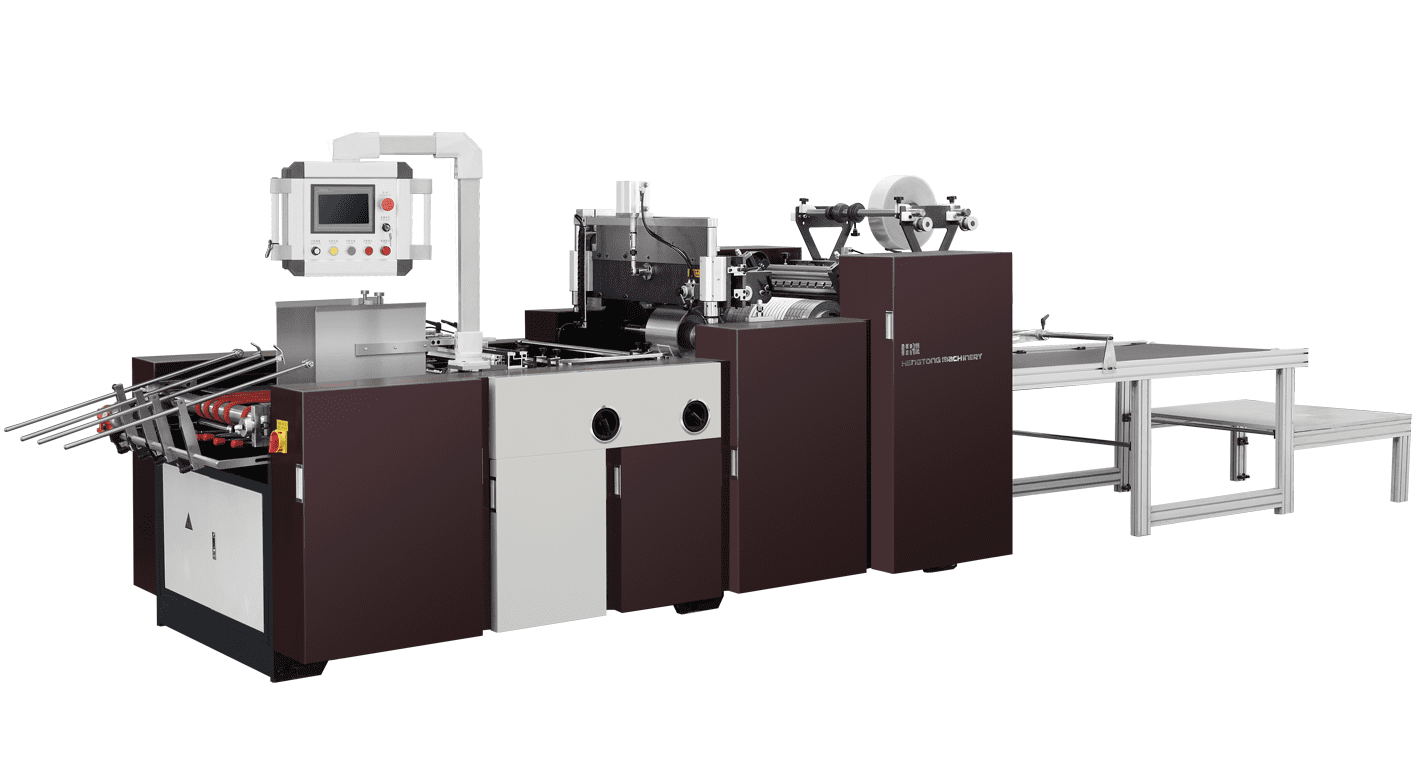

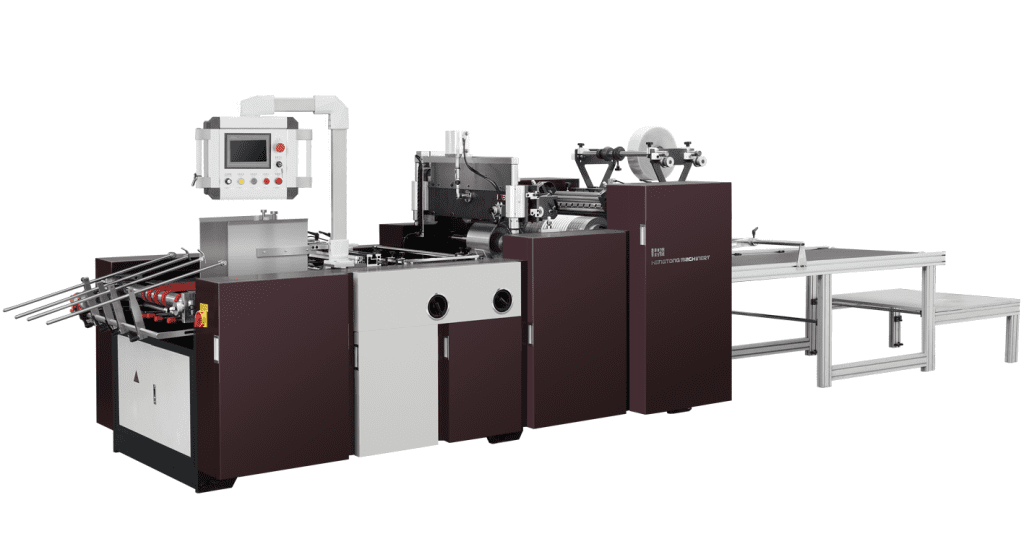

Window Patching Machines are widely used for sticking films on the windows of various color window boxes, color boxes and paper boxes, e.g medicine box, shirt box, etc.

ZKT-700 is the Innovation Machine of Window Patching Machine, Manufactured & Designed by our own Technical Team.

Structure Characteristics:

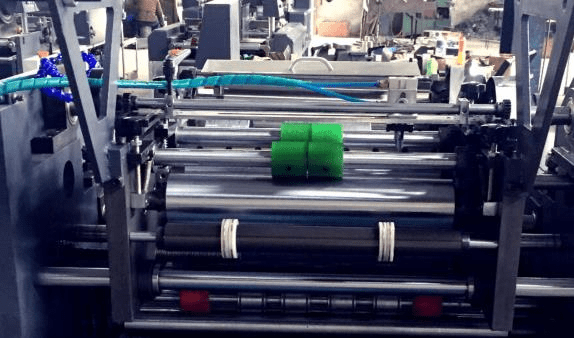

The paper feeder is controlled by PLC with a human-computer interface. The length of paper to be fed without adjustment, so that paper can be input quickly and accurately. Also, it applies to card paper and corrugated paper.

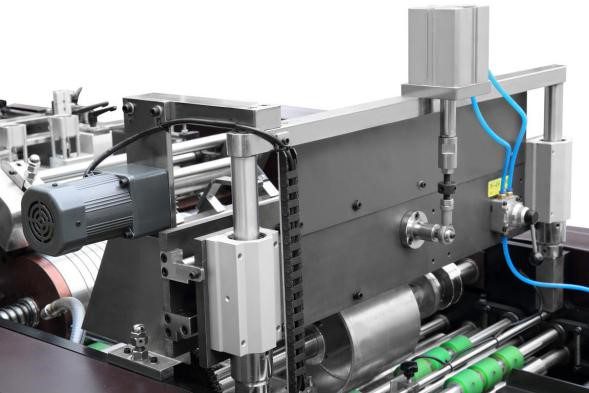

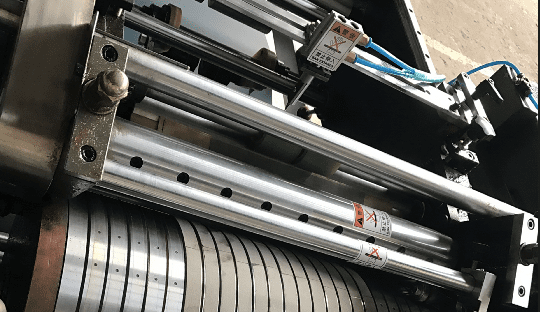

Film Feeding Part is controlled by the Imported Servo System, input the needed Film Length on the Touch Screen, Saving the adjust time and highly precision.

The Gluing Part have been improved, more easily adjustment. the working principle is pneumatic principle, gluing in the basis of the window position, don’t need the big gluing plate, is more easier for cleaning.

Based on the original mechanism, the layout of each section of this product has been improved in order to reduce the adjusting time, so that it becomes more efficiency and friendly.

Technical Parameters:

| Paper Length:

160-680mm |

Paper Caliper:

Paper Box & Cardboard Box 250-1000g/m2. Corrugated / Flute up to 3mm. |

Single Line Speed:

9000-31000 pcs/h |

| Paper Width:

120-700mm |

||

| Film Length:

60-330mm |

Film Thickness:

0.03-0.25mm OPP, PVC, PET, PE etc. |

|

| Film Width

30-400mm |

||

| Power of Pump: 1.5kW, Main Power: 2.2kW | ||

| Weight: 2300kgs | ||

| External Dimensions: 6200x1580x1700mm | ||

Electrical Configuration:

Servo Motor: Japan Yaskawa

Relay: omron

PLC:panasonic

Touch Screen:Kunluntongtai

Frequency Motor: RIBO or Janpan Toshiba ( optional)

Power Switch:Schneider

Swicth Button: Schneider